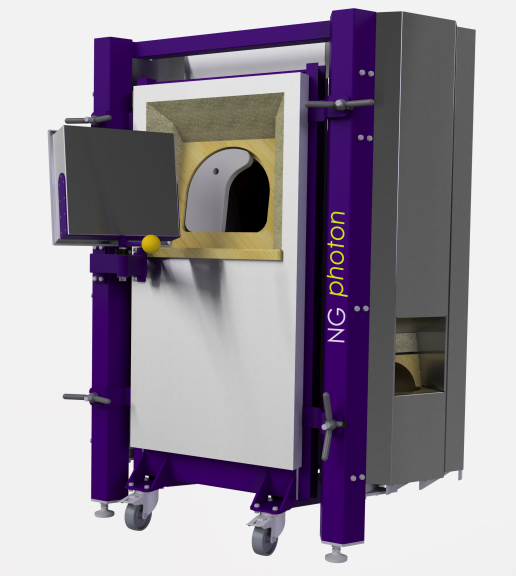

Our newest electric glass furnace NG photon. Developed in 2022. The first modern furnace that reflects the needs of today’s glassmakers. Designed for the most economical operation and the easiest maintenance. Revolutionary furnace heating system with the possibility of controlling each element independently. Very compact in size. The crucible size 40×40 28l, is enough for approximately 55-60kg glass per day.NG photon is designed as hybrid furnace / glory hole.

The furnace output is 25kW/h and is powered by three Kanthal Super 1700 heating elements (Sandvik, SWE).

Consumption depends on the how the furnace is used and the type of glass that is melted.

Average during the working day 0,25-0,40 MW/day

Average during non-use, e.g. weekend 0,10 MW/day

Example of power consumption:

Assuming use of Glasma 705, with a melting temperature 1275 Celsius and working temperature 1120 Celsius.

Melting: approx. 9h

100% power 25kW/h approx. 5h – heating (125kW)

30-50% power 7,5-14,5 kW/h 4h – to hold melting temperature (40kW)

Ramp down to working temperature 0-5kW/h output approx. 2-4h (1,5kW)

Working day (varies depending on the type of work)

30-80% power 7.5-20kW/h approx. 8h (72kW)

When the furnace is idling and doors closed: 2-4kW/h approx.

With these estimates the consumption is an average of approximately (250 kW) 0.25 MW / day, but in reality it may be less as these figures err on the side of a higher level of consumption.

The furnace can be controlled classically via a standard Omron type controller. However it also has the capacity to be operated via a PC and take advantage of all the benefits of a software controlled furnace.

The robust frame of the furnace is made of steel. The body of the furnace is made from a special refractory concrete developed especially for electric furnaces. The thermal resistance of the material is 1700 Celsius and also increased chemical resistance.

NG photon is designed for a freestanding pot, with easy exchange system. Silica or clay pots are compatible.

It has increased insulation versus a gas furnace. There is no chimney and the furnace does not blow hot air and flue gases out of the furnace. The temperature of the surface of the furnace is around 60 Celsius. The furnace runs very quietly. All of which improve the working conditions in the hotshop.

It is worth noting that electric furnaces are heavier that gas, if weight is a concern for your building.

Due to the current increasing energy costs price is only available on request and quotes are valid for a period of one month. Please contact us directly for an up to date quote.